Low-cost pineapple press designed and tested to process the most juice out of a fruit in the shortest amount of time. Farmers can preserve the juice and sell it for three times the profit of uncut fruit.

Testing was a critical tool in refining the design. Thorough testing revealed the amount of force required for the maximum juice output.

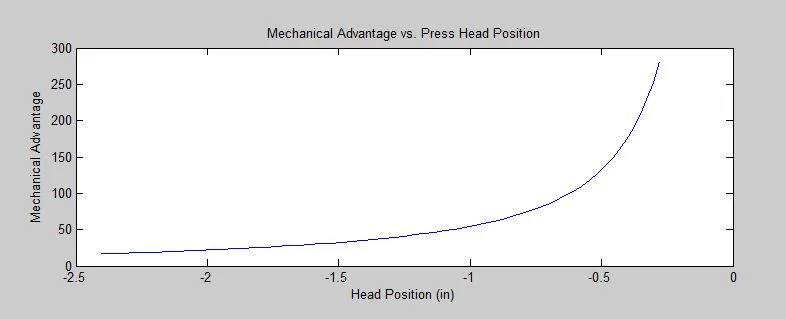

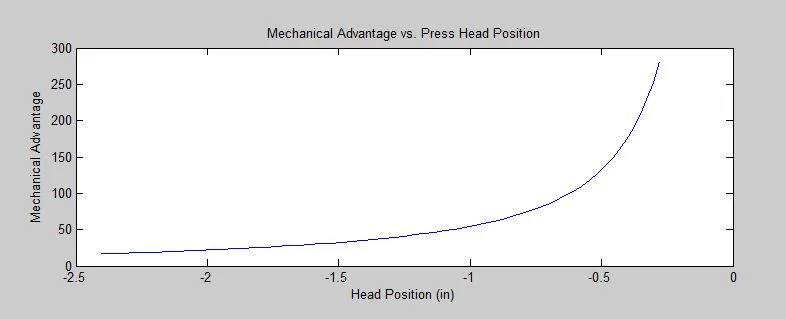

The press mechanism was designed using kinematic synthesis to yield the largest force output at the end of the stroke. This yields more juice for the least amount of user effort.

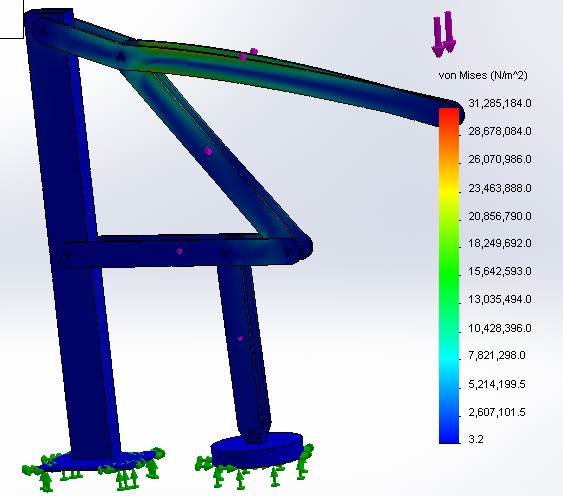

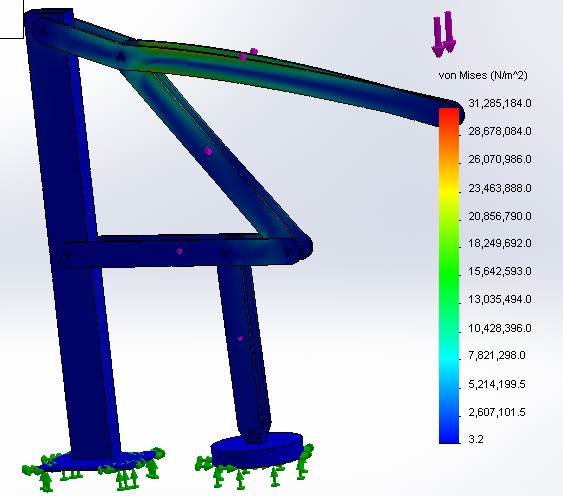

Analytical models ensured the system would not fail under the required loads.

Early prototypes for functional testing.

Original design was hand-carried to Amazonas, Brazil and tested by farmers there. Customer feedback was integrated into subsequent design revisions.

Feedback from the Brazilian farmers allowed for changes in the design like this. Crush plate hole size and placement was altered to maximize juice flow and increased ease of cleaning.